the advantage of machine :

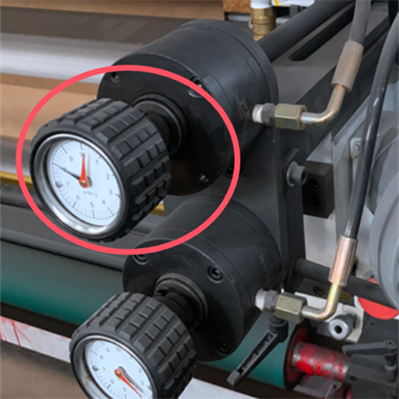

1.All part is imported brand,such as siemens motor ,omron temperature control ,Delta inverter,schneider electrical

2.High precious 0.25mm .high speed 70-80m/min

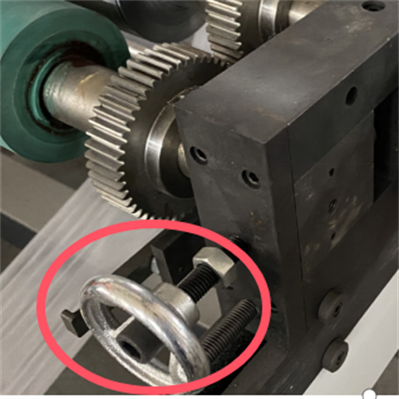

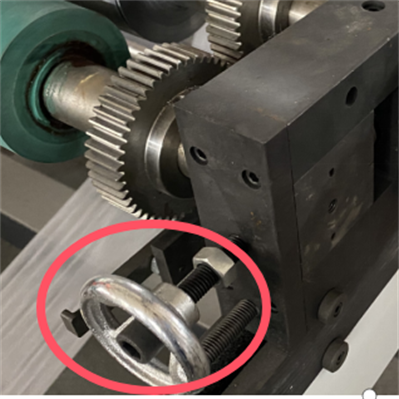

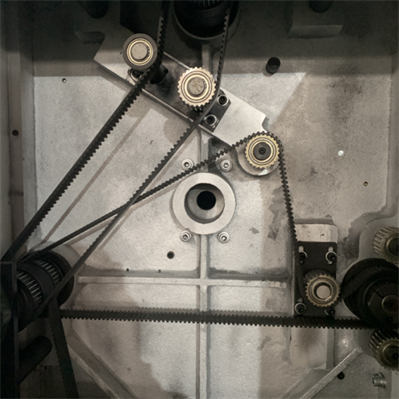

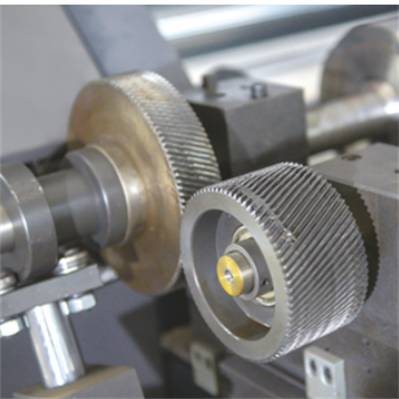

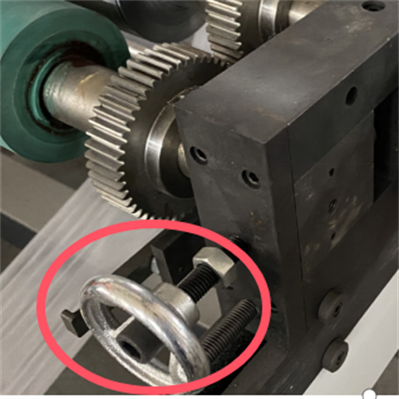

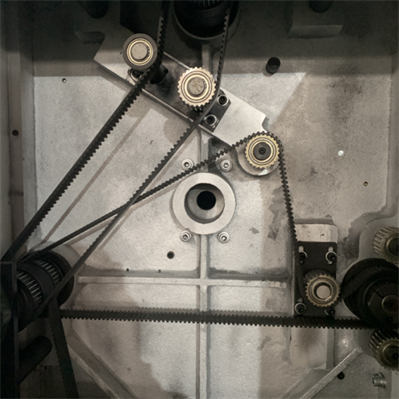

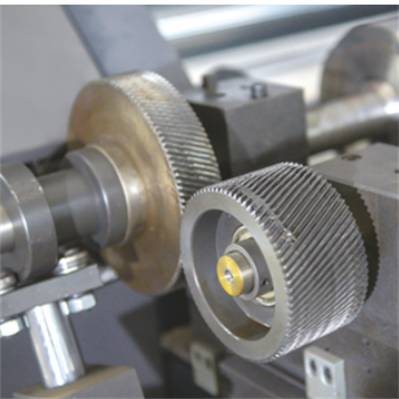

3.Helical gear and belt,no noise and make sure high precious

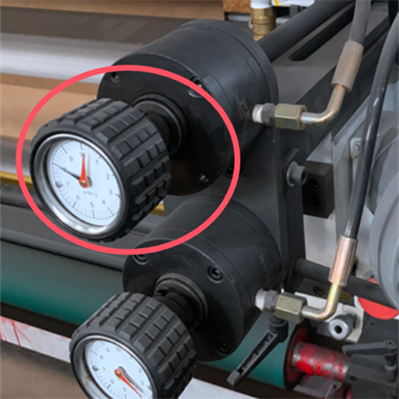

4.With EPC and auto tension .good quality

Technical parameter:

Model of Machine | YT-6600 | YT-6800 | YT-61000 | YT-61200 | YT-61500 |

Suitable Material | PE:15-150um, Paper :15-300g/m sup2;,Nonwoven:15-120g, OPP/BOPP/CPP:10-100um,PVC/NY:10-120um |

Max.Width of Material | 600mm | 800mm | 1000mm | 1200mm | 1500mm |

Max.effect Printing Width | 560mm | 760mm | 960mm | 1160mm | 1460mm |

Printing Length | 220-1000mm

|

Color | 6 color , 6+0 ,5+1 ,4+2 ,3+3 |

Max.Diameter of Roll Material | Φ600mm | Φ600mm | Φ600mm | Φ600mm | Φ600mm |

Printing Speed | 70 m/min 80m/min(with Bigger dryer oven on the top(Optional equipment) |

Accuracy of Registration | 0.25mm

|

Thickness of plate | 2.28mm(let me know if the thickness is different)

|

Total Power | 11.5kw | 15kw | 18.5kw | 22kw | 25kw |

Weight of Machine | 3500kg | 4200kg | 5000kg | 5500kg | 6000kg |

Overall Dimensions(mm) | 5500*1660*2950 | 5500*1860*2950 | 5500*2060*2950 | 5500*2260*2950 | 5500*2460*2950 |

Optional equipment:

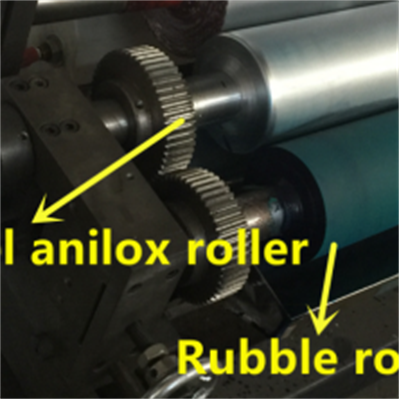

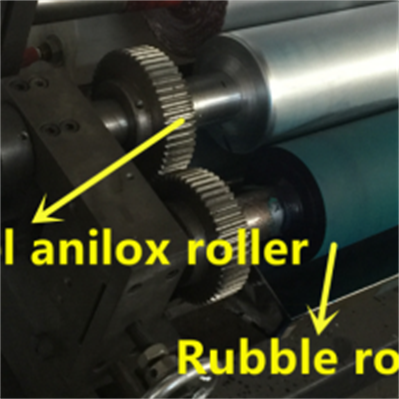

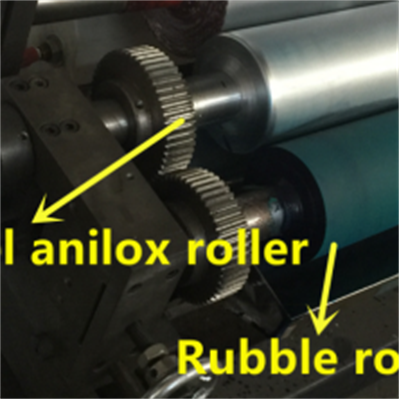

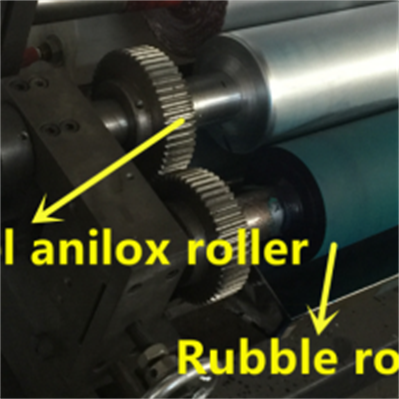

Ceramic anilox roller 6pcs

Hydraulic lifting system (for heavy cylinder)

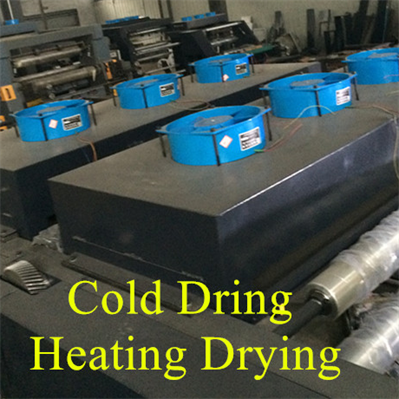

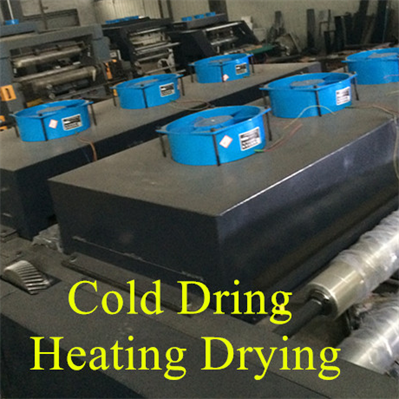

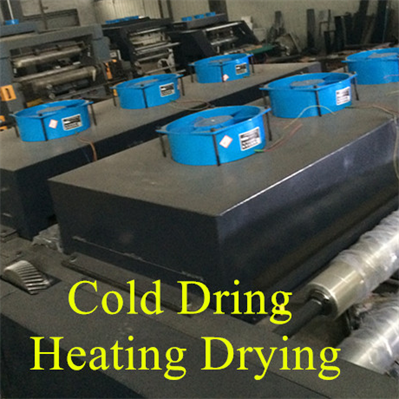

Better dryer oven on the top(Circulating air),speed can up to 80m/min ,It is more suitable for film printing.

hydraulic unwinding rewinding

Details picture of machine

double rewinder+double unwinding .easy change rollers

each color with small oven

each color with small oven

ait pump different size of chromed cylinder .machine with 1 set 400mm cylinder as free

different size of chromed cylinder .machine with 1 set 400mm cylinder as free

how to choose the machine model (50m/min,70m/min,120m/min )

| flexo stack type printing machine | 50m/min speed printing machine | 70m/min speed printing press | YTB120m/min speed printing machine |

How to run:

|

Straight gears,it will be noisy when at maximum speed |

Helical gears, no noise at maximum speed. |

synchronous belt.more silence when high speed |

Electrical Parts | All is made in china | Siemens motor, Delta inverter, Omron temperature control, Schneider Electric | Siemens motor, Delta inverter, Omron temperature control, Schneider Electric, Siemens PLC, WEINVIEW touch screen |

Printing accuracy | 0.5mm | 0.25mm | 0.2mm |

unwinding | 1 unwinding and 1 rewinding | 2 unwinding and 2 rewinding | pneumatic loading and unloading, also with motor (better) |

Gear on the plate roller |

inside the base |   inside the base inside the base

|

The gears are outside the frame ( faster and ink won't fly out ) |

Camera (to see the printing effect). Automatic color registration | No camera | No camera | With camera (to see the printing effect). Automatic color registration (up, down, left, and right) Siemens PLC |

Ceramic anilox roller | (not necessary | can be optional | included |

Chamber doctor blade | none | no need

| included |

|

|

| Each color printing cylinder is equipped with 4 hydraulic cylinders, and the ceramic anilox roller moves in and out hydraulically when the machine starts and stops Convenient horizontal entry |

Plate roller crane | none | none | included

|

Double-sided printing | yes

| yes

| yes

|

Automatic tension, deviation correction | included

| included | included |

Top oven |  normal normal

|

optional: better oven(right one $1000) |

better oven |

Adjustment handle |

|

|

|

Please feel free to contact us if you are not sure which one is more suitable for you

each color with small oven

each color with small oven  different size of chromed cylinder .machine with 1 set 400mm cylinder as free

different size of chromed cylinder .machine with 1 set 400mm cylinder as free

normal

normal