Product Introduction:

flexo printing machine can printing all of rolling film(PE ,BOPP.OPP. PVC. PP ).paper. nonwoven .PP woven

Product Advantage:

1.effective machine speed is 100m/min .

2.Entire machine wall 75mm .it is very stable and ink will not go out even when machine running 100m/min

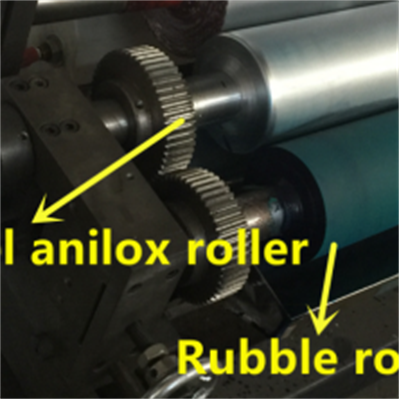

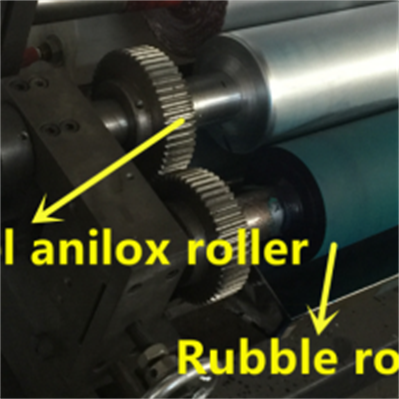

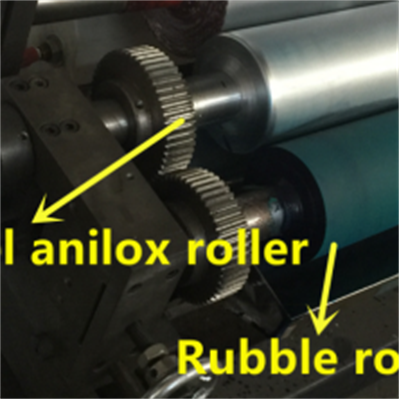

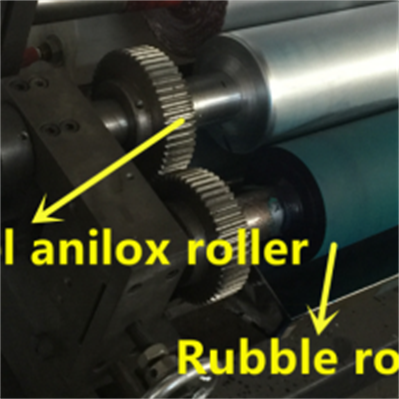

3.Standard machine with ceramic anilox roller(6pcs) .PLC adjust register, video inspecting system.

4.Bigger oven to make sure high speed

Technical Parameters:

Model of Machine | YTB-6600 | YTB-6800 | YTB-61000 | YTB-61200 | YTB-61500 |

Suitable Material | PE:15-150um, Paper :15-300g/m ⊃2;,Nonwoven:15-120g, OPP/BOPP/CPP:10-100um,PVC/NY:10-120um |

Max.Width of Material | 600mm | 800mm | 1000mm | 1200mm | 1500mm |

Max.effect Printing Width | 560mm | 760mm | 960mm | 1160mm | 1460mm |

Printing Length | 220-1000mm

|

Color | 6 color, 1+5 ,2+4 ,3+3 |

Max.Diameter of Roll Material | Φ1000mm |

Machine speed | 130m/min |

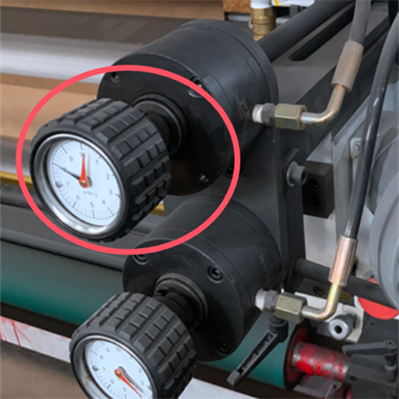

Printing Speed | 80 m/min 100-120m/min(with chamber doctor blade -optional equipment)

|

Accuracy of Registration | ±0.15mm |

Thickness of plate |

1.14mm/ 1.7mm/2.28mm/2.54mm/2.94mm resin plate

|

how to choose the machine model (50m/min,70m/min,120m/min )

| flexo stack type printing machine | 50m/min speed printing machine | 70m/min speed printing press | YTB120m/min speed printing machine |

How to run:

|

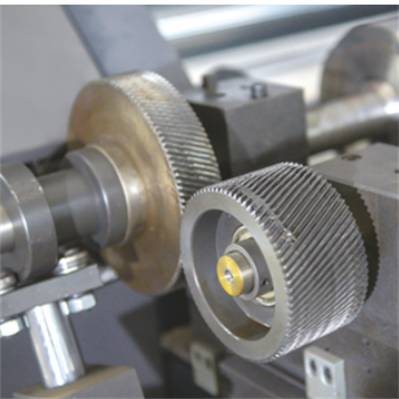

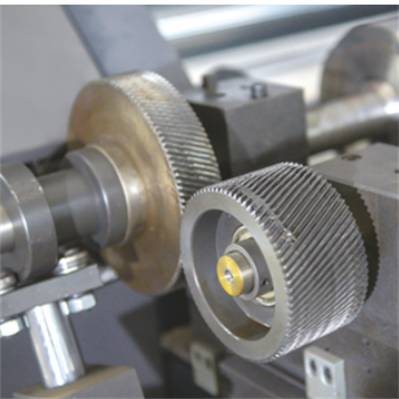

Straight gears,it will be noisy when at maximum speed |

Helical gears, no noise at maximum speed. |

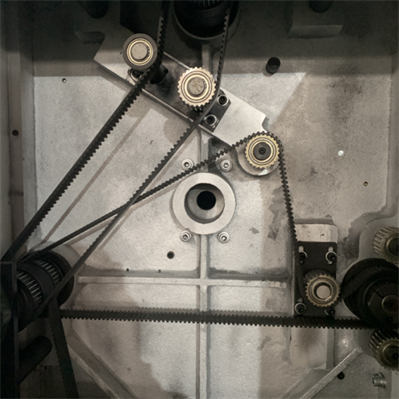

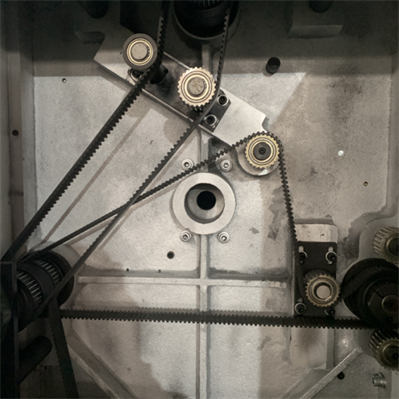

synchronous belt.more silence when high speed |

Electrical Parts | All is made in china | Siemens motor, Delta inverter, Omron temperature control, Schneider Electric | Siemens motor, Delta inverter, Omron temperature control, Schneider Electric, Siemens PLC, WEINVIEW touch screen |

Printing accuracy | 0.5mm | 0.25mm | 0.2mm |

unwinding | 1 unwinding and 1 rewinding | 2 unwinding and 2 rewinding | pneumatic loading and unloading, also with motor (better) |

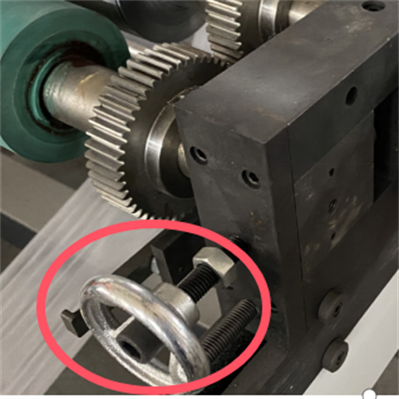

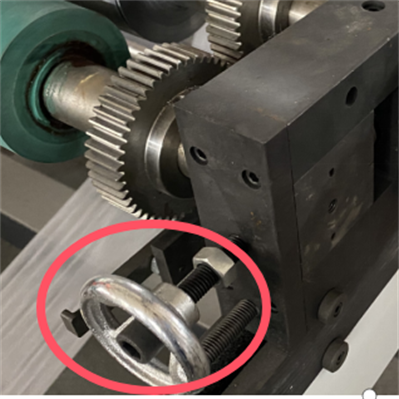

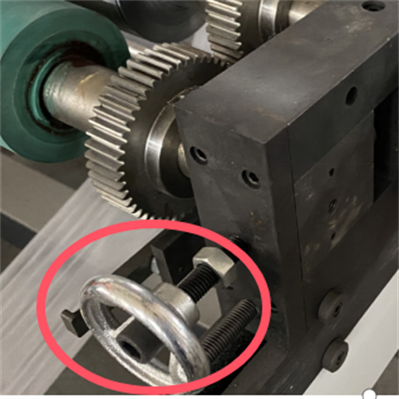

Gear on the plate roller |

inside the base |   inside the base inside the base

|

The gears are outside the frame ( faster and ink won't fly out ) |

Camera (to see the printing effect). Automatic color registration | No camera | No camera | With camera (to see the printing effect). Automatic color registration (up, down, left, and right) Siemens PLC |

Ceramic anilox roller | (not necessary | can be optional | included |

Chamber doctor blade | none | no need

| included |

|

|

| Each color printing cylinder is equipped with 4 hydraulic cylinders, and the ceramic anilox roller moves in and out hydraulically when the machine starts and stops Convenient horizontal entry |

Plate roller crane | none | none | included

|

Double-sided printing | yes

| yes

| yes

|

Automatic tension, deviation correction | included

| included | included |

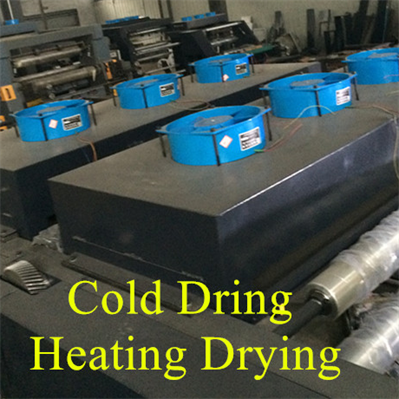

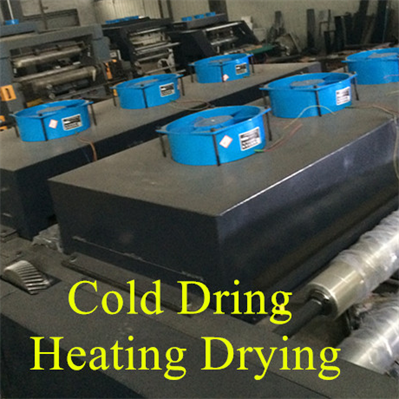

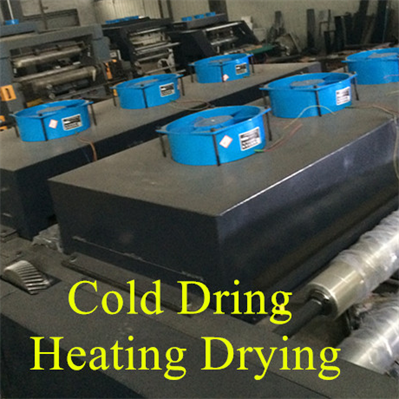

Top oven |  normal normal

|

optional: better oven(right one $1000) |

better oven |

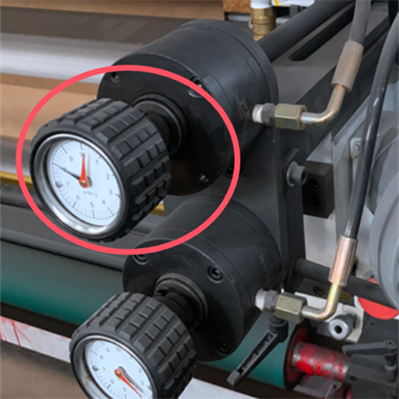

Adjustment handle |

|

|

|

Please feel free to contact us if you are not sure which one is more suitable for you

normal

normal